Fuel system modification (FSM) for paramotors with diaphragm carburetors

by Had Robinson

updated June 15, 2025

Note: The COVID insanity stopped the testing progress, the availability of system components, and the schedule to release it to the public. We are still recovering from this engineered disaster. Before making the FSM available to all, we are continuing safety field tests of the FSM by other pilots, including some who live outside the U.S. It has to be adaptable to a great variety of climates, fuels, engines, and setups. If you are interested in testing the FSM, please contact us.

Quick test to see if the FSM may solve your problem whether it be fuel starvation or a need for increased power output

You must take the time to go through the troubleshooting page to be certain everything is in order. This quick test can help determine whether the FSM is a good solution. The test will also rule out whether the engine has ignition or mechanical problems. If your engine experiences four-cycling (a misfiring that causes the engine to stumble/shake) in the midrange this test will not help as the fuel/air mixture is too rich already.

Take a piece of 1/4" (6 mm) hose and connect it to the primer tube on your engine. If you do not have a primer tube you will have to figure out some way of pressurizing the fuel tank while flying. Make it long enough so that you can get to the end of it in order to pressurize the tank while flying. Make certain that you secure the end of the tube in a convenient spot where you can place it in your mouth AND be sure that it does not get in the propeller.

Pressurize the fuel tank while flying at or near full throttle. It may take a few seconds to see results, especially if there are vapor bubbles in the fuel system.

If pressurizing the system fixes the problem this indicates that the FSM is a good solution to your fuel starvation problem.

1. What is the FSM?

The FSM adds an auxiliary pump to the OEM fuel system that is used on two stroke engines that have the fuel tank far below the engine. It corrects the problem of fuel starvation caused by vapor lock. Vapor lock is created when gasoline is subjected to an excessive negative pressure including excessive heat. It will start to vaporize, forming bubbles that will not allow the liquid fuel to move through the fuel system.

The FSM transports 100% liquid fuel to the carburetor fuel inlet at a constant low pressure of about 0.2 PSI (1.4kPa).

Why do all paramotor engine manufacturers increase the main jet size, including seal the main jet? The more the throttle is opened, the more demand is put on the internal fuel pump in the carburetor. In the environment that the carburetor was engineered for, there is no substantial negative pressure in the fuel system and no bubbles in the fuel stream. When then are bubbles, the pump fails either partially or completely depending on the amount of vapor present. As a result, the fuel/air mixture gets leaner and then engine overheating becomes a serious problem. This is normally fixed by having a larger main jet which increases the fuel to air ratio making a richer mixture. This helps offset the presence of bubbles in the fuel system. As the fuel pump works harder from a greater throttle opening, a greater negative pressure occurs in the fuel stream which, along with heat, creates more gaseous fuel — more bubbles. At some point, the engine may lean out and stall. An annoying side effect of enriching the air/fuel mixture is to make the midrange air/fuel mixture way too rich causing the engine to four cycle (stumble).

The major components of the FSM are:

- A leak-proof fitting installed at the base of the fuel tank

- A pulse-port driven auxiliary fuel pump installed externally at the base of the fuel tank

- Various valves and regulators that work together to maintain the correct fuel pressure at the carburetor fuel inlet.

- A simple manometer that is used to monitor the fuel system pressure and also provides a failsafe mechanism against overpressure

which can occur in the fuel system.

- Fuel recirculation through the entire system to help prevent fuel overheating and vaporization, even under positive pressure.

The design of the FSM creates a slightly positive pressurized fuel system which prevents the gasoline from vaporizing. Gasoline that has bubbles in it will not easily and efficiently move through the carburetor and into the engine. The fuel pump inside the carburetor was designed to only pump a liquid. The more bubbles that are in the fuel, the less liquid fuel will move through the carburetor.

In actual working conditions in an OEM fuel system one can often see bubbles moving through the fuel line into the carburetor. If the amount of bubbles is not excessive, the engine will run well enough. But increase the altitude or temperature too much, the amount of bubbles becomes overwhelming and the engine shuts down.

The figure below illustrates how we measured some of these pressures inside the carburetor. It was fascinating discovering how the Walbro carburetors work and their brilliant design. As the throttle was opened (no FSM), I could watch the fuel pressure at the inlet of the metering lever inlet valve drop. The pump could not keep up. The greater the suction on the gasoline, the greater the occurrence of bubbles. I am unsure why the Italians have not documented this problem.

2. Why install the FSM?

The primary purpose of the FSM is to end fuel starvation. Other purposes are to dramatically increase power output and to recirculate the fuel which helps lower its temperature (tendency to vaporize). This keep the temperature of the fuel as low as possible and helps prevent fuel vaporization before it enters the carburetor. The paramotor manufacturers enriching the fuel/air mix often causes four-cycling" (roughness/stumbling) in the midrange.

The FSM allows the main jet size to be reduced enough to stop four-cycling without causing overheating at or near wide open throttle (WOT). Users of the FSM have to be extremely careful when leaning the system after the FSM is installed! The system should be leaned just enough to stop four-cycling and NOTHING MORE.

Why do we have this problem? Diaphragm carburetors are not engineered to suck fuel from a tank far below the carburetor inlet, as is the case with nearly all paramotors. In addition, gasoline is not manufactured to remain liquid in the presence of a vacuum. Hence, paramotors often have fuel supply problems if things are not perfect. The hotter the ambient temperature and higher the elevation, the greater the problem of fuel vaporization. This is especially an issue if the carburetor pump diaphragm is old and stiff or there are any restrictions in the fuel line e.g., primer bulbs with spring loaded check valves. Every point of the fuel system MUST BE positioned BELOW the carburetor fuel inlet. I cannot express how important this is.

The FSM fixes this fundamental problem by creating the conditions that the engine's carburetor was engineered to operate in: the FSM moves 100% liquid fuel from the bottom of the fuel tank to the carburetor fuel inlet at a constant and very low pressure. As a result, the engine runs more reliably, efficiently, and cooler, especially at WOT. With the reduced main jet size four-cycling goes away. Another bonus is that the engine also achieves greater output at full throttle.

An example is our test engine – a Polini Thor 130. The stock jet is a #130. With the FSM installed and tuned, we were able to decrease the jet size to a #125. We did go down to a #116. However, at sea level it was too easy to overheat the engine. Our reward was a piston with a hole melted in it. The #125 in this case is a reduction in jet size sufficient to eliminate midrange roughness while not causing overheating at or near WOT. On engines with the WB-37 (or its clones), the adjustable main jet can be leaned out in the same manner. Our installation instructions explain how to balance leaning out the main jet while not overheating the engine — and way only pilots with modest mechanical skills should install the FSM. The goal is to have the largest jet possible without four-cycling. Remember: A rich fuel mixture helps cool the engine.

Why not have a slightly pressurized fuel tank? Read this page for the reasons why this may not be a good idea.

3. What is the problem in detail?

For many years, yours truly was plagued by quirky and unexplainable engine stalls while flying, especially when going to WOT at launch. Once during hot weather (over 100º F/38º C), I launched and, in less than 15 seconds, the engine quit. Has anyone had something like this happen? After a few minutes, I would restart the engine and make another attempt to launch but the engine quit soon after becoming airborne. Time to go home. What was going on?

I would rebuild the carburetor, replace ignition parts, check the reed valve, replace the spark plug, replace the fuel filter, and so on. It was crazy. Nothing helped. Anyone reading this knows what it is like. The frustration forced me to take the time to think it all out and apply my training as a once-upon-a-time organic chemist. I studied published material on the manufacture and composition of the various kinds of gasoline. It was an eye opener. After study and experimenting, things started to get clearer.

Typical paramotors have the fuel tank far below the engine. The fuel from the tank is sucked up to the carburetor by a small fuel pump that is inside the carburetor. This negative pressure at the carburetor fuel inlet can range from -0.3 PSI to -0.5 PSI (-1.8 kPa to -3.3 kPa), depending on how low the fuel level is in the tank.

How easily the fuel turns to bubbles in the fuel lines and the carburetor depends on many things including the ambient temperature, altitude, and the formula of the gasoline manufactured in your state or country.

Typically, the negative pressure at the carburetor inlet will not increase enough to cause problems if everything in the fuel system is perfect, especially at or near WOT. Fuel filters, the tank clunk, the fuel inline filter, and the fuel inlet screen in the carburetor can become restricted in various ways that are more noticeable at or near WOT. Some manufacturers make things worse by putting an inline primer bulb in the system. The check valves in the primer bulb are spring-loaded which increases the vacuum on the gasoline. Another issue is the presence of a minimum sized pulse port which causes a problem at WOT, in cold conditions or when the air temperature is high. To reduce restrictions in the fuel system, some manufacturers will eliminate the inline fuel filter (!) or modify the stock carburetor. Then there is cheaply manufactured gasoline which is notorious for vaporizing at the least negative pressure.

Sometimes, a pilot might switch to aviation gasoline (the finest gasoline in the world) but it, too, can cause other problems in some of the larger paramotors, specifically fouling of the piston lands with lead deposits. Like MOGAS (motor vehicle gasoline), AVGAS is NOT manufactured to remain liquid at negative pressures. At the least, we know that AVGAS has a strict formulation for safety reasons and its formula does not change worldwide. As noted further on in this essay, the last resort for the OEM setup is to purchase premixed "racing fuel." It is called this because it is for off-road use and not subject to the pollution rules for motor vehicles.

Another fuel issue can be a tiny air leak where the fuel line joins the fitting that comes out of the fuel tank. This will introduce air into the fuel system which can haphazardly paralyze the fuel system. It is may only be noticeable when at or near WOT. I had to put a video camera near the carburetor on one engine in order to discover this.

These problems in the inherent design of nearly all paramotors work together to create fuel starvation and endless headaches.

Here is a video of what happens when gasoline is subjected to negative pressure while being siphoned from a container into a paramotor fuel tank. The siphon head is about 3' (90cm) above the receiving fuel container. Gasoline in a gaseous state cannot move through the pump valves, filter screens, and passageways designed exclusively for a liquid.

If the fuel filters are clogged or the bottom of the fuel tank is significantly lower than 20" (50cm), the negative pressure on the fuel system increases and so does the possibility of vaporization of the gasoline. Winter mixes of MOGAS further complicate the problem due to the higher vapor pressure of the mix which causes the fuel to vaporize more easily in the fuel lines and, in particular, in the carburetor's internal fuel pump.

Engines experiencing vapor lock cannot achieve full power and even quit after running a few minutes, as this one did. With hot or cold weather, things get worse. Remember that fuel vaporization is progressive as the vacuum and temperature increases. That is, the engine may still run with some vaporization of the fuel. Cold weather stiffens the internal pump diaphragm including the viscosity of the fuel/oil mixture.

Note: Chinese carburetor clones suffer even greater problems from vaporized fuel. NEVER USE THESE CLONES ON A PARAMOTOR!

In order for diaphragm carburetors to function as designed, the fuel pressure at the carburetor inlet should be close to zero or slightly positive.

At sea level, if the ambient temperature is moderate (21C/70F) and every part of the fuel and ignition systems is in perfect order, paramotors usually have enough fuel to operate correctly throughout the entire throttle range – but barely. Any increase/decrease of the temperature, addition of altitude, winter-blend gasoline, modest problems such as semi-clogged filters, low fuel levels, aged carburetor parts, ignition problems, and out-of-spec carburetor adjustments result in fuel starvation. The carburetor is almost always named the culprit even though it is functioning correctly.

As the throttle is opened, fuel flow increases along with the volume of air. The demand on the internal carburetor pump also increases. Rather than just ceasing to pump fuel, it pumps proportionately less fuel the further the throttle is opened. That is, if fuel demand doubles, fuel supplied may be only 175% instead of 200%. If fuel demand triples, fuel supplied may be 250% rather than 300%. These figures vary but this explains the common problem of engines leaning out as the throttle is opened and sometimes stalling or fading at WOT. As the pump works harder, it can create vaporized fuel which paralyzes the fuel delivery system inside the carburetor. Here is a video of a new paramotor experiencing vapor lock from WOT.

Here is another example of vapor lock occurring in a Top 80. This is the classic case of what typically happens when our engines quit or fade. It has nothing to do with some defect or problem with the carburetor but is due to the chemistry of gasoline and the location of the fuel tank. The bubbles of vaporized fuel choked the movement of fuel through the carburetor and prevented the engine from reaching full power.

After a few years and a bunch of prototypes, I discovered something that works which I have named the "FSM" which is short for "fuel system modification". It supplies fuel to the carburetor at a slightly positive pressure so that the fuel always remains a liquid. It has been tested it in all sorts of conditions, including sub-freezing weather, extreme heat, and high altitude. All types and quality of gasoline have gone through the test engines.

The FSM is simple and reliable.

Nonetheless, the FSM must be installed exactly per the instructions because the fuel system now has pressurized gasoline which can create a hazard.

Why haven't the paramotor manufacturers implemented a system like the FSM? It is because of LIABILITY, especially in the U.S. A leak in any fuel system, especially in aviation, is always possible. No fuel system is 100% safe from leaking. Only the German Fresh Breeze paramotors have an emergency method of disconnecting the engine and fuel system from the harness in case of a fire. As of yet, there has never been an inflight fire with a paramotor and we want to keep it that way. The FSM must be installed ONLY by pilots that have modest mechanical skills e.g., have done routine maintenance on small gasoline powered engines, such as changing the spark plug or replacing the carburetor. If you have never used a torque wrench or a spark plug feeler gauge, the FSM is not something you should install.

For those who want to better understand the science of gasoline and vapor lock, they may study this technical review written by Chevron Oil.

4. Benefits of the FSM

- midrange roughness and misfire eliminated by a smaller high speed jet size without overheating

- instant throttle response

- increased power, especially in the larger engines (>100cc) which can average 10% and more

- fuel starvation eliminated – tested to 29F/-2C and below

- vapor lock a thing of the past

- no more engine stalls at launch

- better fuel economy, cleaner burning at higher throttle settings

- no electricity required (unless pilot chooses the exterior electric pump option)

- calibration is visual and easy, no special gauges or tools required

- works with all grades of gasoline, including ethanol mixes and winter blends

- carburetor rebuilds may be extended and done "as needed"

- low cost, lightweight, reliable, simple, durable, and vibration proof

- constant, high volume recirculation of the fuel helps keep it at the ambient temperature

5. Negatives

- Parts of the fuel system are under pressure – leaks can be hazardous!

- Carburetor adjustments are more sensitive – changes in temperature and altitude have a greater effect on the idle settings

- The system requires careful observation in order to ensure safe operation

- More parts to fail

- DIY's must assume all risk! This modification is not for beginners!

6. More details on the FSM

ENGINES THAT CAN BENEFIT FROM THE FSM These would include Top 80, Minari, Vittorazi, Polini, Air Conception, Simonini, Cors-Air or any other two-stroke paramotor that has a diaphragm carburetor and the fuel tank below the engine. Some engines have an internal pulse port, some have an external port. If internal, an external port must be installed, a not particularly difficult task for those who, for example, have gapped and installed spark plugs and know how to use a torque wrench. Some paramotors have fuel tanks that have limited access to mount the auxiliary fuel pump and might also have limited locations where an external tank fitting can be safely installed. Pilots may contact Southwest Airsports via email and photos for suggestions on what to do and whether the FSM can be installed on their engines.

An example of a two-stroke paramotor that would not benefit from the FSM would be the FreshBreeze. It not only has a fuel tank above the engine but also has a float-type carburetor.

OVERHEATING In order to prevent overheating due to lower fuel pump output at wide open throttle, paramotor manufacturers install a larger main jet in the Walbro WG carburetor or specify a richer main jet mixture in the WB and other adjustable carburetors. Minari actually modifies the metering lever spring in the Walbro WB-37. These mods, however, make the midrange rich and cause four-cycling of the engine, especially with the WG and its clones. These are temporary and inadequate solutions.

Instead of some low percentage of the fuel needed near or at full throttle, the FSM supplies 100%. This eliminates the need for increasing the main jet size. When I first starting studying these carburetors I wrongly assumed that the rich midrange was a deliberate design for some reason. That changed when I installed the FSM.

COLD WEATHER Do you fly in cold weather? As temperatures drop into the 40'sF/4-9C, engine stall, hiccupping, and power loss become a problem due to the increase in oil viscosity in the gasoline as well as an increasing amount of un-vaporized fuel which enters the combustion chamber. With a pressurized fuel delivery system, those flying in cold weather suffer less from fuel starvation. However, when temperatures approach freezing and below, the FSM (including all stock paramotors) should also have a preheat system. Just as in any piston driven aircraft, carburetor icing occurs and a preheat system may be necessary for best engine performance. In general, air-cooled engines run better when HOT.

BETTER FUEL ECONOMY Our test engine with a reflex glider averages about 2.4 liters/hour of fuel consumption. This is almost 25% better than without the FSM.

MORE POWER Below is a tachometer reading of 9,080 RPM at wide open throttle with the FSM installed on a Polini Thor 130, stock carbon fiber prop, at high altitude (4,500' MSL) in cold weather (45F/7C). Normal wide open throttle for this engine at this altitude (5,000' MSL) is about 8,400 RPM. Also notice the relatively cool operating temperature of the engine. There is plenty of fuel available when running at or near wide open throttle.

Below is the same engine running in summer conditions with a #122 main jet (eight sizes less than stock). The cylinder head temperature was not significantly higher, just 12C above the usual running temperature, after a wide open throttle 1,000' climb-out. Note: I changed the main jet size back to #125 to lower the chance of overheating and still suppress four-cycling.

Same engine as above but at wide open throttle. The FSM rams fuel into the carburetor so it can get into the engine. The stock engine at WOT goes to about 8,800 without the FSM.

7. Additional notes on the FSM

An inexpensive auxiliary fuel pump could be added to the existing system but its output pressure would be too high and too variable. Excessive fuel pressure (>10 PSI) will force open the inlet needle valve in the carburetor and flood the engine at idle and in the low mid range. The high pressure will also damage the fuel pump diaphragm and valves. There are electrical auxiliary pumps ($90+) that have the right pressure output but they will require a battery, on-off switch, and wiring. Electrical systems adjacent to or in the fuel tank increase the risk of an accidental fire from a short which is why we do not recommend them.

The FSM can be adjusted to maintain an average pressure of about 0.28 psi/2.0 kPa at the carburetor fuel inlet.

An external pulse port is required to operate the auxiliary pump. Some engines, including the Top 80, have an internal pulse port so an external port must be added. It is a relatively simple task for amateur mechanics to drill and tap a hole in the crankcase near the reed valve assembly for a 6mm x M6 brass barb fitting. The fitting, the right sized drill, and tap are included in the FSM kit for engines without an external pulse port. The pressures in the crankcase are not more than a few PSI, thankfully.

Other than the liability issues, why have the paramotor manufacturers not created something like the FSM?

- The tank fitting must *NOT* leak. It took some time to find one that would do the job for an HDPE tank.

- There is the additional cost of the FSM.

- The

FSM adds

complexity to the fuel system – but this is inevitable if we want a permanent and bulletproof solution to the tank location problem.

- The FSM must be installed and maintained with care. I cannot overemphasize this!

Another method that has surfaced recently is pressurizing the fuel tank with an external pump. But something about pressurizing a fuel tank did not make sense to yours truly. Well, a customer of ours purchased a used Miniplane Top 80 from a 3rd party that partially used this method. It stopped running and the pilot brought it in to us for repairs. He said, "By the way, I had to replace the fuel tank the other day because it split open."

What!?

The 3rd party had closed off the tank vent to allow the gasoline vapor pressure (about 6-7 PSI) to fix the vapor lock/fuel starvation problem. Along the way somewhere, he forgot to remove the vent cap and the constant gasoline vapor pressure was enough to split the tank open. THESE TANKS WERE NOT DESIGNED TO BE PRESURRIZED! Our customer was not flying the paramotor at the time, thankfully. So, what happens when a tank splits open while flying and gasoline leaks out onto a hot engine? Do you want to find out?

The FSM auxiliary pump must be mounted at the base of the fuel tank. Additional lines and an oil scavenging system are required in order to prevent the pulse chamber of the pump from filling up with oil, stopping its operation.

Below is an idling engine with the FSM installed. It pumps about a liter per minute, far more than would ever be required, even in the largest paramotor. Note the low level of fuel in the tank. The average FSM system consumes 4-5 liters/hour, depending on the glider and the weight of the pilot.

Other solutions for the fuel tank location problem typically involve internal carburetor modifications, special metering lever springs, non-pressure regulated auxiliary fuel pumps, and over-sized jets.

None of these fix the root problem better than the FSM.

An electric in-tank pump (as is used in snowmobiles and jet-skis) could solve the problem but it would still require the VLCP (Very Low Constant Pressure) regulator system. The high pressure from these pumps would either ruin the carburetor's internal fuel pump or open the metering lever valve which will flood the engine and why the VLCP regulators MUST be used! The cost of a premium pump would be well over $250, add significant weight, and would require a battery and wiring. But such a configuration is neither practical nor cost effective for the small volume production of paramotors. Having electrical wiring and terminals around gasoline also adds risk. Note: this is an INTERNAL pump, not an EXTERNAL pump. The latter is an option for those who lack the skills to install a pulse-port in the crankcase.

Band-Aid type fixes may slightly help but they only work well under some conditions (cold/hot/high altitude) but not another. With these partial/temporary solutions carburetor tuning becomes difficult (or impossible) and unpredictable. It also makes changing an OEM carburetor for a replacement more expensive when an ordinary stock carburetor will work just fine.

Pilots flying at all altitudes and in all conditions will benefit from the FSM. Nonetheless, high altitude operation will still require adjustments of the carburetor jetting. Cold temperature operation (near or below freezing) require cold weather modifications i.e., increasing the high speed jet size and/or installing a preheat system.

Because of decreased main jet settings, midrange performance modifications are unnecessary, an important benefit of the FSM.

Note: If ethanol fuels are used, pilots must allow for more frequent maintenance of the FSM system. Ethanol, a powerful solvent, tears up all flexible fuel system parts including the VLCP regulators and fuel lines. If at all possible, *avoid* ethanol fuels! Gasoline in some parts of the world also has corrosive additives to prevent mildew and other weird problems often found in the tropics. These additives increase the routine maintenance of the FSM.

While the FSM fixes the root fuel supply problem, engine performance can still suffer due to the same reasons as with the stock fuel supply system such as:

- incorrect carburetor adjustment

- overdue carburetor maintenance

- clogged filter or muffler

- water and other contaminants in the fuel

- incorrect metering lever height

- leaking, crushed, improperly located, or defective fuel lines

- worn out or incorrectly adjusted spark plug

- ignition or mechanical issues e.g., bad reed valve, worn out cylinder, etc.

The FSM is not a cure-all for a poorly maintained or incorrectly adjusted engine. It is a permanent fix of the negative pressure in the fuel supply system.

8. Testing and analysis of the FSM

Aside from in-house testing of the FSM, Chris Jokinen (Darwin, Australia) has been testing it on an Air Conception Hybrid 130cc. He flies in grueling conditions for a paramotor – very hot ambient temperatures and high humidity using gasoline formulated for the tropics. Here is his report. Instead of an open oil drain for the auxiliary fuel pump oil scavenging system, he mounted a catch bottle which creates less mess. We added this improvement to the FSM kit. Thank you, Chris, for helping improve the FSM!

Once the FSM is installed, the main jet may be CAREFULLY changed to a leaner value. In the Walbro WB carbs, this means an adjustment of the HS jet. In the Walbro WG carb it means replacing the stock jet with a smaller size. For example, the stock jet for the WG on a Top80 is 116. I have changed it to a 112 which eliminates the four-cycling in the midrange. (Your location and altitude may require a different value!) The FSM operating instructions (given when the FSM is purchased) give the details on how to SAFELY lean out the carburetor without burning a hole in the piston, etc.

9. Requirements for installing the FSM

- A cylinder head temperature gauge and tachometer

- An external pulse port fitting of 5/32" (4mm) ID or greater. If needed, we can supply a pulse port kit of this size. Smaller ID port sizes may work but some of the features of the FSM may not function and bigger engines may not achieve maximum performance.

- The carburetor must b4e a genuine Walbro (the best), Tillotson, or Tryton. Clones may not function properly with the FSM.

- It is critical for safety that there are (2) independent ways to shut down the engine in case of an emergency. Here is one method for engines without a choke. ALWAYS, ALWAYS CHECK YOUR STOP ENGINE SWITCH WHEN FLYING WITH THE FSM!

- The engine must be in good mechanical condition.

WHEN THE ORDER FOR THE FSM IS PLACED AND PAID FOR, WE WILL SEND YOU THE INSTALLATION MANUAL. STUDY THE MANUAL TO SEE IF THE FSM IS SOMETHING YOU CAN INSTALL. IF YOU CHANGE YOUR MIND BEFORE WE SHIP THE FSM, 100% OF THE PRICE PAID WILL BE REFUNDED. WE WANT ALL PILOTS TO HAVE SUCCESS WITH THE FSM.

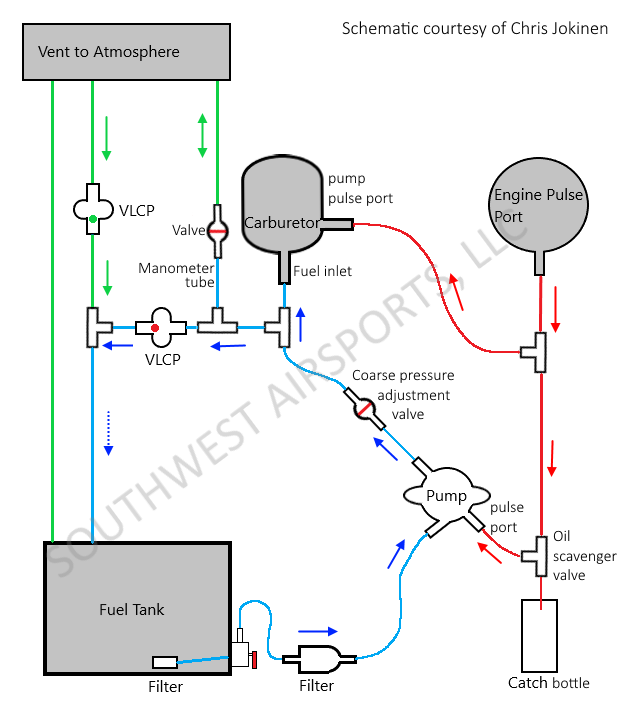

10. FSM basic schematic

Note: this schematic does

not include some minor parts of the FSM.

Note: this schematic does

not include some minor parts of the FSM.

Key

- blue lines – contains liquid gasoline. Note: the fuel line between the auxiliary pump and the course pressure adjustment valve contains gasoline at 6 PSI. All other fuel line areas have a pressure of 0.5 PSI or less.

- red lines – pulses that power the carburetor and auxiliary fuel pumps (some engines will not have a pulse line going to the carburetor)

- green lines – air

- green, red, or blue dots/arrows indicate flow direction. The dotted arrow is fuel + air

- VLCP's – Very Low Constant Pressure regulators, red or green type

11. FSM parts

The parts for the FSM are constantly being tested. Replacement parts, including pump rebuild kits, are available from Southwest Airsports. The VLCP's should be replaced each time the carburetor is rebuilt (approximately every 25 hours) as they both share the same types of materials that eventually harden and decay in the presence of gasoline. These parts are not expensive. Because we buy in bulk they are actually less than anything found online.

The FSM and the kits listed below include FREE shipping to continental U.S. addresses ONLY.

WARNING: the Chinese are the worldwide masters-of-cheap. Pilots must be sure of all sources. We continually discover their new imitations of pumps, fuel line, and carburetors which look like quality made items but are junk. The worst Chinese products are the carburetors, filters, and fuel valves. These fakes usually do not work properly in the FSM.

A. FSM kit $290 (not yet available for purchase on our shop page)

B. External pulse port kit option

- To order

- Installation manual for the pulse port kit

C. Fixed carburetor jets for the Walbro WG

- replacement jet – the size must be greater or equal to #98. Each jet is custom machined in our shop to closer tolerances than the genuine Walbro jets. Once the FSM is installed pilots may cautiously lean out the high speed air/fuel mixture to eliminate four-cycling in the mid-range.

D. Electric fuel pump option $275

- FACET 12VDC electric pump with fittings

- 12V LiPo 2200 mAh battery (does not include LiPo charger)

- necessary wiring

E. Tank quick-disconnect option $36

- This optional fitting may be installed after the bulkhead fitting to allow the fuel tank to be detached from the paramotor without having to remove fuel lines from fittings. It is ethanol resistant. Most pilots will not need this option unless they routinely remove the fuel tank for some reason.

F. Options for the FSM kit

There is no charge for option 1, 2, or 3. Pilots MUST choose at least one of these (3) options.

- OPTION #1 – 6” x 1/8" (3mm) ID fuel line for carbs with 1/8" (3mm) fuel inlet + reducer fitting + zip tie

- OPTION #2 – 6” x 3/16” (5mm) ID fuel line for carbs with 3/16” (5mm) fuel inlet + 9mm clamp

- OPTION #3 – 6” x 1/4" (6mm) ID fuel line for carbs with 1/4" (6mm) fuel inlet + 10mm clamp

- OPTION #4 – 3/16" (5mm) extra fuel and pump line needed for additional distance beyond 20" (50cm) of bottom of tank from carburetor inlet. The extra distance is in increments of 6" (15cm) minimum order 1’ (30cm) – $ 2.30/0.5'(15cm).

12. Installation, troubleshooting, and maintenance

The figures below show the general locations of the FSM parts. Current locations vary as we improve the functionality and reliability of the FSM. Installation instructions sent out with the FSM have the latest and best locations of parts.

Fuel tanks can have many variations. Some tanks must have the tank fitting installed on the bottom. Other tanks may require another vent/drain fitting at the top of the tank. We can supply additional leak-proof fittings, as needed.

Technical manuals included with the FSM kit

The manuals below are emailed to pilots at the time of FSM purchase and when updated.

1. Installation manual – detailed information on the FSM installation procedure

2. Operating manual – first time use and setup of the FSM

3. Operating manual – how to operate the FSM after initial setup

4. Troubleshooting manual

NOTICE: INSTALLATION OF THE FSM IS DONE AT YOUR OWN RISK. THE MODIFIED FUEL SYSTEM CAN LEAK GASOLINE WHICH COULD BE A HAZARD. YOU MUST BE CERTAIN THAT ALL FUEL LINES AND FITTINGS HAVE BEEN PROPERLY INSTALLED AND CLAMPED SO THAT NO FUEL LINE CAN SLIP OFF A FITTING AND LEAK FUEL. BY PURCHASING THE FSM KIT OR PARTS THEREOF FROM SOUTHWEST AIRSPORTS YOU ASSUME ALL RISKS FOR THE INSTALLATION OF THE FSM. IF YOU HAVE ANY DOUBTS CONCERNING YOUR SKILLS AS A MECHANIC, DO NOT INSTALL THE FSM. BY YOUR PURCHASE OF THE FSM, YOU AGREE TO THESE TERMS AND CONDITIONS.

![]()