Carburetor intake air preheat system for paramotor operation in cold weather

by Had Robinson

updated April 1, 2023

Paramotor engines can experience fuel and carburetor problems when the air temperature drops below 70F/21C. The colder it gets, the worse the problems become which include:

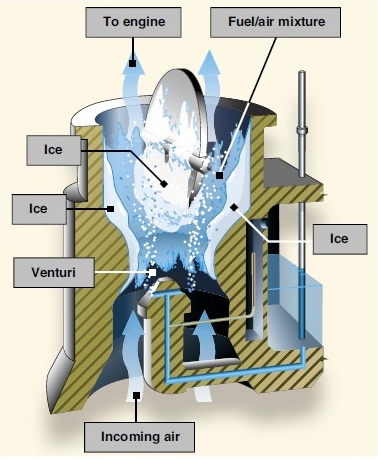

- Carburetor icing due to the pressure drop on the engine side of the carburetor, lowering the air temperature to below freezing.

image courtesy of https://aviation.stackexchange.com/ - An inability of the fuel to fully vaporize and mix with the incoming air.

- Oil in the gasoline getting more viscous, which prevents it from moving through various filters, passageways, and jets. The effects of thickening oil on the fuel pump are variable. Note: the installation of the FSM greatly assists fuel delivery to the carburetor when temperatures are cold, very cold, and well below freezing. It will be available soon.

In order for the fuel/air mixture to burn efficiently in any engine, it must be in a vaporized state. Paramotors do not have a preheat system that sufficiently warms the air and fuel entering the carburetor so that the mixture will become fully vaporized in cold weather. When the air temperature is 70F/21C, the engine quickly becomes hot enough in a few minutes to fully vaporize the fuel. Typically, head temperature is around 140F/60C at that time. The temperature of the crankcase is much less but still hot enough to ensure vaporization.

When the temperature drops even more, things change and it takes longer for the engine to heat up. When the temperature drops below 50F/10C, the head may be 270F/130C but the crankcase may be just warm. The fuel/air mixture reaching the inlet port below the piston may not be fully vaporized, especially if the carburetor is well insulated from the engine, a typical configuration used to prevent vapor lock in hot weather. How do we achieve 100% vaporization of the fuel/air mixture when the weather gets COLD?

The preheat system described here heats up the entire fuel-air flow entering the engine and ensures the required 100% vaporization of the fuel/air mixture. It will work with any paramotor and is best with those that have active cooling systems (a fan) or have a passive cooling systems with a shroud. Paramotors that have passive cooling shrouds e.g. Moster 185 and the Minari will require more effort to regulate engine cooling as needed in cold weather. Once a pilot gets the proper venting of the intake completed, it is a simple and quick task to remove/install the preheat system as needed. Once the preheater is built, it takes about 5 minutes to install it, a much easier task then changing the high speed jet size.

The principle of operation is to take air that has passed over the engine cooling fins near the exhaust manifold and route it to the carburetor air intake. The system must be adjusted so that engine cooling is still maintained i.e. the running temperature is within the correct limits. In any case, it matters not at all whether the air entering the carburetor is a bit warm or even hot. Ordinarily there is a wide range of temperature where no change in the venting of the cooling system is required. Operating with a preheat system can be done during the cold season or any time the ambient temperature is below 70F/21C.

For pilots who routinely fly in sub-freezing temperatures this system could be modified to also send heated air into a flight suit. If someone out there tries this, contact me and I will post it. Flying in cold air is like sitting for an hour or more in a ski chairlift on a cold day. There is all this warm air going to waste!

Parts required

-

Galvanized hanger strapping – thin metal with holes in it that is commonly used by plumbers to hang pipes.

- Automobile air intake pre-heater hose –

3.8cm/1.5" or

5cm/2" diameter x 45cm/18", depending on the clearance between the back of the engine and the propeller. Commonly available tubing from auto parts stores

e.g. AutoZone is made of aluminum and paper. The most durable tubing is pictured below and has a tempered steel spring core but costs more.

- Duct tape – gray fabric type. Black will blend better with the engine parts, if that is important. I tried aluminum tape (evident in the photos below) but I found

out that it is harder to use and tears too easily. Use only cloth duct tape!

- Nylon zip ties

Special tools needed

- Dremel type tool with a cut-off wheel that should be used to cut tubing with a tempered spring steel core. Note: You will destroy ordinary metal cutters if they are used to cut tempered spring steel.

Installation

The tubing must be modified to fit the cooling exhaust port on the engine. If there is no forced air cooling, cut the opening as in the photo below. The part of the tubing that receives the hot air must fit closely to the exhaust port area of the engine. The other end of the tubing must be cut to fit the intake of the air box. The Moster 185 has a small air box intake which will accommodate a smaller diameter heater hose.

NOTE: WITH THE PREHEAT SYSTEM, THE AIRBOX IS NOT NEEDED AND CAN BE DISPENSED WITH IF IT IS EASIER TO INSTALL THE PREHEAT SYSTEM. This would be true for the Top 80 or any engine where the airbox intake is not particularly accessible.

Both ends of the tubing must be closed with duct tape. The "hot air input end" is where the amount of cooling is regulated. Opening up the "hot air input end" allows more air to flow past the cooling fins of the engine and out rather than be re-directed to the carburetor. For example, when it is very cold (below freezing), the opening can be about the same or smaller than in the photo below. In above freezing temperatures, it was about right to remove about 1/2 of the remaining duct tape. It does not need to be exact. Better a hotter engine than a cooler one when flying in cold weather. If the hole is cut too large, it is easy to make it smaller with another piece of duct tape.

Note: pilots *cannot* properly adjust this preheat system unless a CHT is installed!

Zip ties must be used to keep the tubing away from the propeller. Remember: everything that is *not* firmly attached always winds up in the prop. The tubing on the engine here is firmly held by either the hangar iron or zip ties. The duct tape is only used to reduce air leakage or to adjust the system.

Below are photos of the completed preheat system which may be helpful when installing it on your engine.

It is hard to see in the first photo below but the lower ends of the hangar strapping use the redrive mounting bolts as anchors. All engines have head nuts/screws which are very convenient for mounting the upper ends of the hangar strapping. Do not even think of using duct tape to secure the tubing to the engine.

In the photo below, the cooling exhaust port end of the tubing is completely covered which caused the engine to get a too hot, even in very cold conditions.

The entire system can be removed in a few minutes once the flying weather warms up permanently. That is, it is not necessary to remove the preheat when ambient conditions warm up during the winter/spring briefly. The Polini Thor below has the FSM installed which ensures that fuel will reach the carburetor inlet under all conditions. With the preheat system, engine output was still at least 10% greater than specifications for that engine. Throttle response is instant which is contrary to what pilots will experience in cold conditions.

Note the white zip tie securing the carburetor end of the preheat pipe to the engine frame. This connection is only to ensure that the hose will not get into the propeller if, for some reason, the duct tape gives way. Pilots must think of how many ways the pipe can get loose and take appropriate measures to secure it.

Remember to keep your eye on the CHT often when using a preheat system. Fly safely!

![]()