High Altitude (HA) jet information and installation for the WG carburetor

by Had Robinson

updated November 17, 2024

Discussion

- DO NOT MAKE ANY CHANGES TO THE CARBURETOR UNLESS YOU HAVE FIRST INSTALLED A CHT. BEFORE DOING ANY MODIFICATION GET A GOOD IDEA OF WHAT THE AVERAGE RUNNING TEMPERATURE OF YOUR ENGINE IS. IT IS EASY TO BURN UP ENGINES. (Our shop is littered with burned up engines.)

- USE ONLY APPROVED OILS AND ETHANOL-FREE GASOLINE, IF POSSIBLE. ETHANOL FUELS NEED LESS OXYGEN THAN PURE GASOLINE WHICH EFFECTS JETTING. Sad to say, ven premium 100% pure unleaded gasoline varies seasonally in most U.S states and may cause vapor lock during cold weather operations. Installing the FSM can fix the problem but it is still in the testing phase.

If you do the changes correctly, you will not harm your engine but improve its operation.

I live at 5000’ elevation and did your high altitude jet and throttle plate mod and it made a huge difference. - from a pilot in the Rockies

All engines are designed to run at or near sea level. When they are operated at high altitudes (HA) e.g. 4,000' MSL the same volume of air contains less oxygen and so the engine requires less fuel. The carburetors, accordingly, need to be able to have the air/fuel ratio leaned out.

To accommodate these requirements, many engine manufacturers provide carburetors that have adjustable low and high speed jets. However, the Walbro WG that is used on many of the smaller paramotors has a fixed main jet. Apparently, the original engine that the WG was designed for (a Husqvarna chain saw) tended to overheat easily and burn up so a fixed main jet was installed in the carburetor. In the world of 2 stroke engines, this is unique.

Thankfully, the main jet on the Walbro is easily accessible and can be changed to a smaller size. The proper sized main jet is required so that the engine runs smoothly and efficiently. A rich mixture at full throttle may limit power output and cause the engine to run roughly. Midrange operation, similarly, requires a leaner mixture at high altitude but having a smaller main jet has less effect (unless the FSM is installed).

I have used an HA jet at sea level but the risk of overheating was much greater. If you weigh over 170 lb. I would not change the main jet size if you fly at sea level. Also, I recommend increased caution when correcting midrange problems if operating at or near sea level.

Running a paramotor above 4,000' MSL will cause your midrange and high end performance to suffer if the carburetor is not modified. The most annoying are the problems in the midrange and this should be corrected (see #3 below) before changing out the main jet. Typical of full throttle HA use with the stock jet is carbon buildup inside the combustion chamber, clogging of the decompression port (if there is one), fouled spark plug, roughness, stuttering, and lower engine output. The higher you fly, the richer the mixture and the worse are the problems. There also will be a decrease in fuel economy.

EFI ignition Putting an EFI system on a paramotor would solve the HA problem but such a system has other problems. Particularly, it greatly complicates the fuel delivery and electrical systems. The computer which meters the fuel delivery has to be programmed and sensors must be mounted all over the engine to measure things like the exhaust gas stream temperature and O2 content, ambient air pressure, air temperature, engine speed, throttle valve position, engine vacuum, and intake air velocity. Think about it.... What is gained over a carburetor? Pilots can efficiently fly over a great range of altitude with an EFI system but who flies more than a few thousand feet above launch? If it is done, it is only for a brief period. Kits run around $600 and would take dozens of hours to install and calibrate. The Walbro carburetors are simple, cheap, and work well, considering. A greater problem with an EFI system is that it must have a source of pressurized fuel. Anything less than a submerged in-tank high pressure fuel pump would work. Any pump that is not at the bottom of the fuel tank will result in vapor lock of the fuel system. I think it is a lot of trouble for not much of a performance increase.

Changing the jet size There are two ways to decrease the main jet size in the WG. One way is to modify the jet itself (time consuming and not accurate). The better way is to install a smaller jet, a much more accurate method. We have the HA jets which are machined in our shop (FREE shipping included) for the various engines that use the WG.

Jet sizing for HA use

1. Learn the parts of the carburetor (it helps to print out the parts diagram). Note: The values in parentheses below are the carburetor part numbers given in the diagram. If you have any doubts about the condition of the carburetor or it has been more than a year, rebuild it before making any modifications. Your fuel system must be in perfect working order. Dispose of mixed fuel that is older than a month. Oil exposed to gasoline will decay slowly and lose its lubricating properties. Also, it is essential to install a CHT and tachometer on your engine. It might save burning it up if you make a mistake somewhere.

2. Watch the Walbro carburetor service video if you have not already.

3. It is best to correct the low and midrange problem first by modifying the throttle valve plate (#9) or installing the FSM (when it becomes available).

4. To modify/change out the main jet, remove the metering diaphragm cover (#6) and the metering diaphragm.

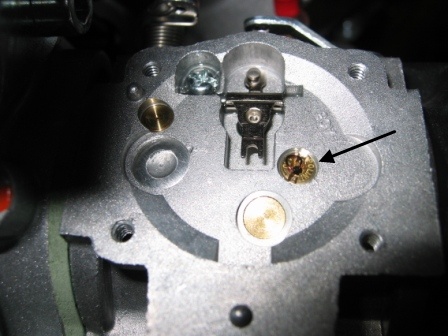

5. Using the correct screwdriver (it must fit snugly in the slot of the jet), unscrew the main jet (#16) from the carburetor body.

6. Change the jet (best) or temporarily modify it. The Top 80 (small engine) HA jet is a #112. For HA operation of the Thor 130 (large engine), install a #128 jet. If the FSM is installed, the main jet can be downsized much more e.g. for larger engines, a #125 or smaller may work well. Downsizing the main jet lessens roughness (4 cycling) in the midrange. If this is done, watch the running temperature of the engine carefully as reducing the main jet can quickly result in overheating.

7. Reassemble the carburetor. Use a felt tipped pen to mark the surface of the metering lever diaphragm with the jet size.

8. Adjust the low speed system.

9. Test fly the engine, watching the cylinder head temperature. Engines that have had the HA jet modified/replaced may run 10ºC to 20ºC hotter and have noticeably higher power output. If it starts to run over specs, shut it down immediately and do what is necessary to enrich the fuel/air mixture. There is a lot of trial and error reducing the main jet size.

Be alert to a quick increase of temperature or the engine having "hiccups" in the midrange. These are signs that you are running too lean. In general, "TAKE IT EASY" until

you are certain that the new jetting will not cause overheating.

![]()