Fuel filter information

by Had Robinson

updated February 6, 2022

There are (3) fuel filters in most paramotors: a pickup tube filter, an inline filter, and the inlet fuel filter screen which is inside all diaphragm carburetors. These three filters are replaceable. The inline filter is the most important of the three. If it is a cheap one or is missing, the inlet filter screen in the carburetor will likely clog and cause a lean condition (and overheating) or power fade/stall at or near full throttle.

WARNING: DO NOT USE ANY KIND OF INLINE PRIMER BULB WITH A PARMOTOR FUEL SYSTEM. THE SPRING-LOADED CHECK VALVES IN THE PRIMER BULB CAN CAUSE FUEL STARVATION!

A. Pickup tube filter (clunk)

Most clunks are the inexpensive variety like this one. It does not have a steel ball to weigh it down but relies on the weight of the metal frame of the clunk, instead. This clunk is used on weed whackers and similar small engines because they have no inline filter. It is not recommended for paramotors because of its low flow rate and how easily it tends to clog, especially if ethanol fuels are used.

Below is a typical paramotor OEM clunk. It contains a piece of steel but it is only for adding weight to the clunk. A plastic clunk without some sort of metal weight might float in the gasoline.

Because most paramotors have priming systems, check valves in the clunk are unnecessary and may be removed to enhance fuel flow.

Generally, a clunk with a filter of fine, porous material (like those in the above photos) are only necessary if there is no inline fuel filter on the engine, which is rare. Unfortunately, these types of filters clog easily with dirt including goo that is created when using ethanol fuels (when the fuel comes in contact with water). Cold weather can also choke fuel movement through this kind of filtering material due to the oil in the gasoline getting more viscous as the temperature drops. Before there was gasoline with ethanol, clunks served an important purpose by helping keep water out of the fuel lines.

INCREASING FLOW THROUGH A CLUNK Like the clunks above, those with any kind of filter are useless! The filter is unneeded and, when it gets clogged, causes vapor lock a.k.a. fuel starvation. New paramotors almost always come with high quality inline fuel filters which replaces the clunk filter. Some OEM clunks even have FINE SCREENS which shouild be removed. Remember that the inline filter does the work of keeping debris and goo out of the fuel system.

Here are the steps to improve fuel flow in your paramotor: 1. Remove the filter from the tank (it has to be fished out or the tank tipped upside down). 2. Drill (2) 6mm (1/4") holes in the sides of the clunk. Leave the stell ball/object inside the clunk so it will not float. Make certain there are no filter screens in the clunk!

Some OEM clunks have nipples with a narrow ID. This can restrict fuel movement, especially at or near full throttle. Use a 1/8" (3mm) drill bit to widen the ID of the nipple. Remember that ease of fuel flow through the entire fuel system is a critical requirement for good engine operation and preventing fuel starvation.

CLUNK FLOW CHECK To determine if a clunk with a filter is in order is easy: Disconnect the fuel line at the inlet side of the inline fuel filter. Put a cup or container underneath the end of the disconnected fuel line so gasoline does not go everywhere. Pressurize the fuel tank with the primer tube or squeeze the primer bulb. Gasoline should pour out the end of the fuel line and not dribble.

CHEAP CLUNK AND CHEAP FUEL LINE Here is a photo of what typically happens to the clunk fuel line over time. The line will split at the clunk and will separate from the fuel pickup tube and then bounce around inside the tank. Pilots should take a look in their fuel tanks periodically to be sure the clunk is not only attached but also does not have a split fuel line attached.

B. Inlet valve filter screen

The inlet valve filter screen in all diaphragm carburetors can only be cleaned or replaced if the carburetor is disassembled. It should always be checked if there are any fuel delivery problems in the engine i.e., fuel starvation. NEVER OPERATE AN ENGINE WITHOUT THIS SCREEN. Please see the carburetor rebuild page for photos and more info.

C. Inline fuel filter

(If desired, go to the filter installation steps directly and skip the discussion below)

Recommended inline fuel filters for paramotors which are available from various Internet sources.

Miniplane OEM fuel filter Oregon 07-124 WIX 33001 (the WIX has the highest capacity)

Do NOT buy inline fuel filters sold in auto parts stores (other than the WIX 33001 which some stores stock). They are of inferior quality and will not block the small particles that clog the inlet valve filter screen and other small passages in the carburetor. Unfortunately, most inline filters are rated at 40 or more microns which is fine for 4 stroke engines but not enough for 2 stroke engines which have an inlet fuel filter screen that must be kept perfectly clear.

If you fly in cold weather <60F/15C, you should consider using a filter with a much larger filtering area than the OEM, such as the WIX 33001. The OEM or Oregon filter may choke the flow of fuel because of the increased viscosity due to the oil.

Why bother with a high quality filter? In two stroke engines, the fuel filter is also the engine oil filter. It must be able to trap all of the grit and other contaminants in the fuel and lubricating oil.

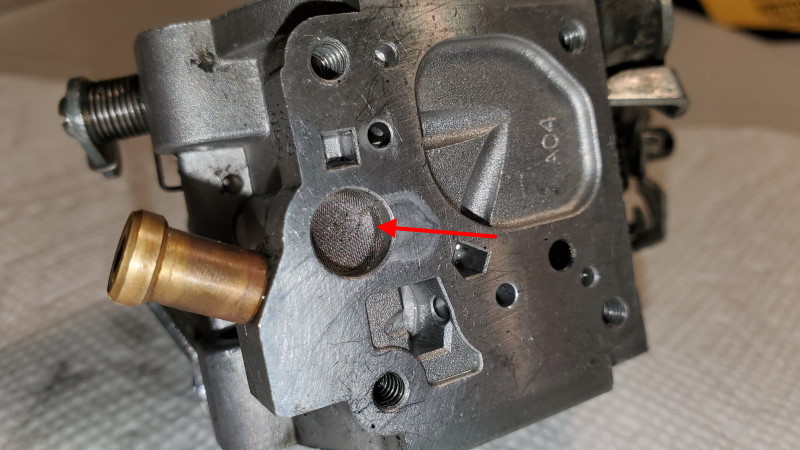

The engine that had this carburetor had trouble leaning out and stalled under load. Is it any wonder? Dirt in the fuel got inside the carburetor and clogged it. The arrow points to the small cavity on the outlet side of the fuel pump, just before it goes through the inlet needle valve filter screen. The pilot had an inline filter but it was one of the sintered bronze types (see below) commonly used on lawnmowers.

A CLOGGED FUEL SYSTEM IN ANY HIGH PERFORMANCE ENGINE IS A POTENTIAL DISASTER. FUEL STARVATION IS THE #1 CAUSE OF ENGINE DAMAGE IN PARAMOTORS.

Aviation engine forums (ROTAX) note that paper filters are the best because they have the finest filtration media – around 12 microns vs. 40+ micros for sintered bronze or the pickup tube filters (clunks) sitting at the bottom of fuel tanks. The non-paper filters do not trap the small particles which will clog the pump inlet fuel filter screen in the carburetor. A clear filter housing must be used because pilots need to be able to periodically check that the filter is not clogged or damaged.

Here is a clogged inlet filter screen (diameter about 6mm) with a new one to the right. Sintered bronze filters will allow contaminants to reach the carburetor and why they should not be used. This engine experienced fuel starvation and overheated. Unbelievably, some paramotors do not come with an inline fuel filter.

Here is another photo of a clogged inlet fuel filter screen. The pilot of this engine had trouble at full throttle – when fuel demand outstripped the supply. It is likely that this engine had no inline fuel filter or that it was the useless bronze sintered-type filter. I continued to be amazed at how simple maintenance will ensure our engines run well.

Below is a photo of a sintered bronze filter. The media is just not fine enough to stop small particles from passing through. These work satisfactorily in 4 cycle lawnmower engines, more or less, but in nothing else.

Fuel pump diaphragm showing signs of water contamination in the fuel, probably from using ethanol blends.

Below is a photo of the WIX 33001 inline fuel filter (L) and a similar filter (R) sold by the auto parts stores. The problem with the WIX is that it is about twice the size of the OEM filters and should only be used on the bigger paramotors (130cc and up). If you fly in very cold weather, this filter has better flow characteristics because of its large filtering area. The WIX filtering media is 12 microns but who knows what it is of the filter on the right in the photo below. The fuel line nipples on the WIX have barbs which ensure that the connection will not leak. The filter on the right will tend to leak fuel because it has no barbs on the nipples. In addition, the fuel lines may come off if subjected to a pulling force. Does it make sense to put a cheap fuel filter on a $2,000 engine?

The WIX filter should not be used on the Miniplane Top 80 or other small paramotors because of its large size which requires it to be mounted above the carburetor (see photo below). The top of the fuel line will be even further above the level of fuel in the tank and will create a greater vacuum on the fuel. This will increase the chance of fuel vaporization at the most inconvenient times.

This photo shows the WIX used in the FSM. Note how it is installed by the use of a short piece of 1/4" (6mm) automotive fuel line and a zip tie. This type of mounting parts on a paramotor is secure and reduces the effects of vibration.

The Oregon 07-124 is a commercial grade chainsaw filter rated at 10 microns. However, the filter has burrs (ridges) on the nipples from the injection moulding process which can be a source of air leaks, even when clamps are used. Remove the burrs with a razorblade. Why does Oregon not clean them up? It would involve another manufacturing step and increase the filter's cost. Otherwise, these are excellent filters and superior to OEM's from Italy because they have no metal parts which can corrode and rust. The Oregon's low fuel flow rate is fine for OEM paramotors but not for those that have the FSM installed.

Depending on use, fuel filters should be replaced yearly at a minimum. As the filter is used, its flow rate declines from the presence of invisible particles. This is not much of an issue in automobiles but it is for paramotors because they sometimes run at full throttle for a relatively long time. Fuel starvation is a huge problem for paramotors and must be avoided to prevent overheating.

Note: ethanol fuel blends and fuel that is contaminated by water hasten the deterioration of paper fuel filters.

Installation instructions

Here are some tips on fuel line installation, the various types, and where to purchase.

- Mount the filter and the lines BELOW the carburetor in order to decrease the vacuum on the fuel at the tank. This will help prevent vapor lock (fizzing of the fuel).

- If existing tubing is hard to remove, heat the tubing with a hot air gun or a hair dryer until it is almost too hot to touch. The

tubing will easily slip right off of the fittings without damaging anything. If the heated air blown on the skin is painful, decrease

the heat setting. It is possible to melt inexpensive fuel line so be careful.

- When connecting the new filter, heating the fuel line as above is helpful. Also, putting a small amount of

100% silicone grease on the fittings and inside the tubing

eases the installation. It will also

help keep it from splitting, a common problem with anything less than premium fuel line.

- Be certain to run fresh fuel through the system when replacing a fuel filter. Here's how: Before connecting the fuel line from the filter to the carburetor, prime the system as if for starting. Put the end of the open fuel line in a container of some sort, and force fuel through the new filter into the container. At least a 1/2 cup (125 ml) should be enough. The fuel in the container can be put back in the fuel tank, if desired. If the step is not done, the inlet valve filter screen in the carburetor may become clogged.

- Complete the connection of the fuel line to the carburetor.

![]()