Walbro & Tillotson carburetor info and others

by Had Robinson & others

updated December 15, 2024

The WG8 and the Husqvarna #503282001 (WG10) are identical except that the latter has the main jet pressed in. This does not make it easy to change. The main jet is pressed into a 5.5mm hole in the carburetor body. It would have to be pulled out via drilling and tapping (M3 x 0.7 mm) the existing jet, inserting a 3.0 mm screw, and pulling the jet out. The 5.50 mm main jet hole in the carburetor body would have a brass insert pressed in that is drilled and tapped with a M4 x 0.50 mm hole to accomodate any sized Walbro jet. The insert could be lightly peened in so that it would not fall out. Christian Barman has been helping us with this project. We will keep everyone informed of the progress.

The WB37 and the MPE090 are tuned identically and have the same parts. The former has an external pulse port and the latter, an internal port. There are two variants of the WB: the 32 and the 37. The 32 has a smaller venturi. I have never seen the 32 on any paramotor in the U.S. The metering lever springs and the throttle plates are different but the repair kits are identical.

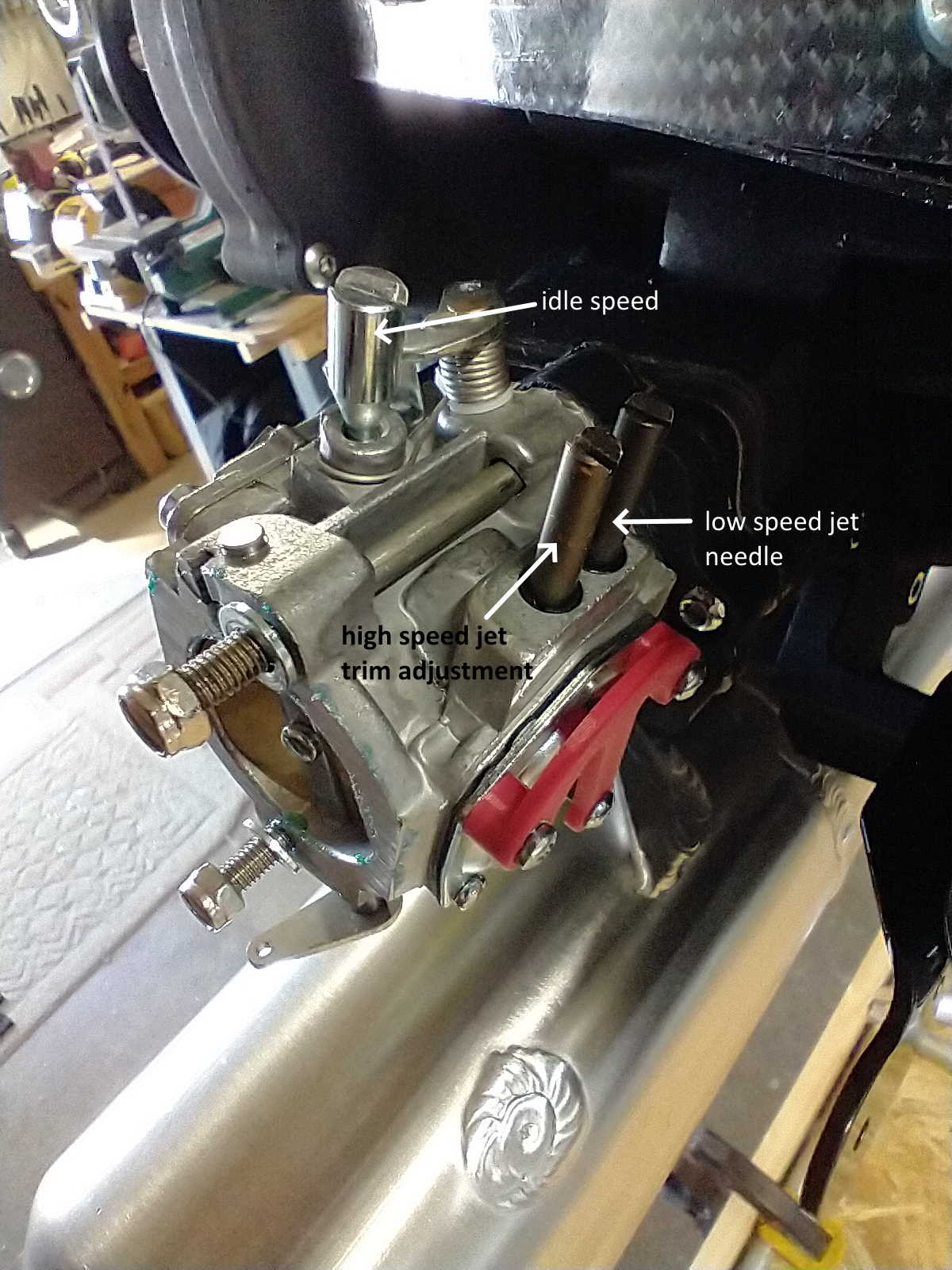

The Tillotson carburetor coming on some new paramotors is tuned largely the same way as the WB and serviced the same as the WG. Be aware that this brand of carburetor does not have the quality of the Walbro. The Tillotson has a fixed main jet (size 102) with a high speed trimmer needle that can change the mixture. Please see photo below.

Zama has this simple technical guide of how a diaphragm carburetor works. It is the place to begin if you have never worked on a paramotor engine and is a bit easier to understand than other manuals.

Service Topics for the WG & WB carburetors (Tillotson similar)

Note: We will slowly be adding information on the Tillotson carburetor on this page

Special tools needed to service a carburetor – see the Special tools needed

If your engine is not running right or not at all, first go to Troubleshooting your paramotor. It is the right place to start and has a checklist.

Adjustment Tillotson HT – TBA

Adjustment WG, low speed – Study "Rebuilding and tune up" below first to be sure you understand the basics.

Adjustment WG, high speed – The WG high speed system has a fixed jet and cannot be adjusted. In certain circumstances e.g. high altitude, the main jet can be replaced with a different one.

Adjustment WB/MPE090 – idle, low, and high speeds

Air box – the air box usually has an internal air filter. It must *NOT* be saturated with oil. It is unnecessary and can restrict air flow into the engine. Periodically wash the filter in hot soapy water, as needed.

Air filter – see "Air box" above

Black lever on the WG throttle shaft – What is it for?

Buffering chambers in the WG – The inlet and outlet of the internal fuel pump have them.

Choke – What does it do? Why have it? Many models of the WB, sadly, do not one. But why would any big chainsaw carburetor need a choke?

Clunk – see "Fuel filter" below

Cylinder head temperature gauge – Not having a CHT is like driving a car without any gauges or warning lights. Most of the time you don't need them....

Diagram WB/MPE090 – the diagrams are for most models, variations are minor.

Diagram WG – the diagrams are for most models, variations are minor. Note: the Thor engines (100 and 130) have a different sized main jet. This diagram does not identify the priming lever.

Dimensions of the Walbro's – by Gerry Farell and Had Robinson – This information compares the dimensions of various Walbro carburetors and is helpful if you are considering changing from the WG to another obsolete Walbro model that is floating around. The WB would work on the smaller engines (80cc to 130cc) but there might be more problems/roughness in the midrange. Zama does not make any carburetor that is compatible with paramotors.

Disassembly – see "Rebuilding and tune up part 1 and part 2" below

Disassembly WG (technical, not for ordinary disassembly needed to test or rebuild) by Richard Cobb with some notes by Had Robinson

Drips – Two stroke engine carburetors drip/leak fuel by design. It cannot be helped.

Engine performance issues – see "Performance tuning" below

External pulse port installation – some models of the WG and Tillotson only. It is needed for accessories including an auxiliary fuel pump

Failure points of diaphragm carburetors – There are (3) common points of failure. Also, see "Performance issues, general" and "Performance issues, midrange" below

Fuel draining from the carburetor back into the tank when engine is off

Fuel filter – What kind/type to use? If you choose poorly, the engine will also run poorly, if at all. Removal and installation tips. The fuel system MUST be purged of old fuel and air when changing out the fuel filter.

Fuel pump – see Fuel system test The fuel pump design of the WG and the WB carburetors are marginal and will not work well except in perfect conditions. You must rebuild the carburetor at least once a year or more often if ethanol fuels are used so that the fuel pump diaphragm and check valves are in perfect order.

Fuel pump vacuum – 5" H20 (dry) 7" H20 (wet w/ fuel) It should be obvious why paramotors with fuel tanks way below the engine experience fuel starvation often (and why we developed the FSM).

Fuel starvation – this is what it looks like. It is caused by vapor lock. To fix this, see "Fuel system test" below.

Fuel system modification – the FSM dramatically fixes fuel starvation and most performance issues of all diaphragm carburetors (still in the test phase).

Fuel system test – A quick and easy way to tell if the system is functioning properly.

Fuel line size – Use Tygon® LP1100 low permeation fuel line (ethanol resistant) or equivalent. It is available from Miniplane-USA. Do NOT use ordinary vinyl fuel line as it will become stiff quickly and stress the connections on the tank and engine. Auto parts stores do NOT have the right type of fuel line. These sizes are for the Miniplane Top 80. Other engines generally use 4mm (3/16") line exclusively.

- carb to inline filter ID 3mm (1/8") x OD 6mm (1/4")

- inline filter to fuel tank ID 4mm (3/16") x OD 8mm (5/16")

Gasket problems – (internal pulse port carburetors only) The gasket between the carburetor and the reed valve can get misaligned and block the pump pulse port.

High altitude use – greatly improve performance at high altitudes and/or in cold conditions by reducing the main jet size (fixed jet) or turning CW an adjustable main jet.

Installation – (internal pulse port carburetors only) Be ABSOLUTELY CERTAIN that the carburetor-reed valve body gasket is properly aligned with the pump port hole. If this gets misaligned, the engine may still run but poorly.

Jets (fixed) for high altitude use – Walbro WG only see "High altitude use" above

Jet modification – Walbro WG only. Here is a way to temporarily decrease the size of a fixed main jet that it is not permanent

Jet sizes for the Walbro WG – Stock jet sizes (Main jets Top 80 (smaller engines) #116, Thor 130 (larger engines) #130). We custom machine jets of all sizes. See "High altitude use" above for info on high altitude jets.

Leaks – see "Drips" above

Metering lever adjustment – Tillotson TBA ; Walbro WG 0.7mm ; Walbro WB 1.19mm - 1.59mm. WG only: If your metering lever diaphragm has a tang instead of a button, set the value to 1.7mm

Metering lever function – The ZAMA (a Walbro clone) has a much better service manual (see "Service manual (ZAMA)" below which explains how the diaphragm carburetor works. Also, see "Modifications" below for more information on the metering lever.

Metering lever height variation WG – the WG carburetors on new engines have one value and Miniplane's Italian service manual specifies another. Which is correct? What's going on?

Metering lever spring length WG-8 – 15.0 mm long when new. Replace if less than 14.9mm WB/MPE090 – [not known at this time]

Midrange roughness, stutter, and four-cycling – see "Performance tuning, midrange" below

Models in the Walbro WG series – The different WG models are a result of changes in the U.S. EPA air pollution regulations.

Modifications of the Walbro WG carb by Gerry Farell – TECHNICAL discussion (not useful for most pilots). Additional notes by Had Robinson.

Overhaul – see "Rebuilding and tune up" below

Overheating – This will destroy an engine. What causes it? How is it prevented?

Parts Diagram – see "Diagram" above of the respective carburetor model

Performance issues, general – Here is the info for troubleshooting a motor. It includes information on the ignition as well as the carburetor

Performance tuning – Here is how to modify the WG or WB carburetors to increase performance and eliminate roughness in the midrange.

Performance tuning, full load – See "High altitude use" above.

Pick-up tube filter – see "Fuel filter" above

Pop-off pressure – Tillotson TBA, Walbro WG & WB 1.2-1.3 Bar (17.5-19.0 psi) Rest pressure > 0.68 Bar (10 psi.) The pressures must be within specs.

Priming the fuel system on a paramotor – see "Starting your paramotor" below.

Purging the system of fuel – It must be done if a paramotor is to be stored for more than a few weeks, especially if you are using ethanol fuels.

Rebuilding and tune up part 1 – START HERE. This link is for the official Walbro BASIC video (21 min). Tillotson similar. It is helpful for those who are not familiar with diaphragm type carburetors. It is THE place to begin and includes testing of the pop-off pressure. Sections 1-5 are the most relevant for users of the WG and WB carburetors. The video has examples of carburetors ruined by ethanol fuels.

Rebuilding and tune up part 2 for the WG & WB carburetors. Tillotson similar. Once you have studied part 1 above or already have a basic knowledge of diaphragm carburetors, continue here.

Removal of carburetor – It is usually held to the engine by (2) nuts which are just next to the air box flange. NEVER over-tighten these nuts. Some engines have long socket head screws which hold the carburetor to the engine. Remove the fuel tubing, throttle cable, choke wire, and throttle return spring.

Replacement for the Walbro WG – Miniplane has contracted with Tillotson Ireland for a clone model# HT21A 038 of the Walbro WG-8. Tillotson trashed emails sent by us requesting information and repair kits for this carburetor.

Reed valve – A loose reed valve body or a clogged pulse port will affect the fuel pump. The mounting screws must be torqued to the correct value.

Service video for Walbro carburetors – see "Rebuilding and tune up part 1" above

Service manual for all Walbro carburetors – (not very helpful and out of date) This is for all Walbro diaphragm carburetors, including the WG (the series used in obsolete chain saws and now paramotors). It has some good theory discussions but the ZAMA manual is better.

Service manual WB – this Walbro manual (dated 1995) is for a WB that was used on a now-obsolete chainsaw. It is helpful if you have no information on the WB used on your engine. The WB is very close to the WG per operation. The main difference is that the WB has an adjustable high speed needle jet and a different metering lever adjustment value. The WB also does not have a choke. The ZAMA service manual (below) is also good to study.

Service manual (ZAMA) – this service manual is just a few pages, concise, and simpler to understand than the Walbro manual. Pages 2-6 are the relevant sections.

Service tips (from ZAMA) – ZAMA explains why measuring the pop-off pressure is rarely necessary. It's the REST pressure that is important. Also, using the wrong type of pump can easily over-pressurize the fuel pump chamber and damage the diaphragm.

Service video – see "Rebuilding and tune up part 1" above

Stall – going to full throttle, the engine stalls or the pilot bends over and the engine stalls. What are the causes?

Starting your paramotor – How to start your engine the first pull. Note: this technique will not work on engines with vertical carburetors (Minari).

Storage – if you are storing your paramotor for more than a few weeks, purge the fuel system.

Throttle cable – Cleaning, modifications, and cruise control info. For kill switch issues, see kill switch problems.

Throttle return spring replacement – Improve throttle response, lessen hand fatigue with this modification/replacement.

Throttle shaft play – A worn out shaft leaks air and will cause the engine to idle poorly. A bad inlet needle seat will also cause this.

Tillotson HT21A 038 Parts diagram Repair kit: RK-28-HS Diaphragms kit only: DG-7-HS Pop-off: 25 psi Rest: 13 psi Metering lever height: 1.80mm Dimensions: venturi 22.4mm throttle 27.0mm intake 32.0mm Tuned very much like the WG but the high speed fuel mixture is adjustable within a safe range. I noted that the throttle spring is stiffer than the WG.

photo courtesy of Dan Taylor

Troubleshooting chart – for those who are not familiar with how a diaphragm carburetor works, this chart from ZAMA can be a great help. None of the so-called troubleshooting charts are particularly useful. More often than not there are multiple problems with the carburetor.

Tune-up – see "Rebuilding and tune up parts 1 & 2" above

Vapor lock – it is the most common fuel problem in paramotors due to the near universal location of the fuel tank far below the carburetor

Warming up – when is a paramotor warmed up sufficiently and ready to fly? When the cylinder head temperature reaches 70-80ºC, the fuel/air mixture is sufficiently hot enough to ensure that it is 100% vaporized and that the engine will not be fuel starved and potentially overheat. Overheating can happen very quickly.

Welch plug removal and installation

![]()