Metering lever height variation in the WG and others

by Had Robinson

updated January 2, 2020

Over the years, I have noted that Miniplane ships out new Top 80 engines with the metering lever (ML) value on the carburetor set to 1.7mm which is different than the value given in their Italian service manual (0.5mm - 0.7mm). Extensive testing here has demonstrated that Miniplane's Italian service manual value is correct rather than the value measured in carburetors on new engines. Why does the carburetor come from Walbro with an incorrect ML value? It is probably due to the fact that there are two different kinds of ML diaphragms supplied by Walbro. This was pointed out years ago by Richard Cobb. In any case, the ML height must be adjusted to the correct value for the specific ML diaphragm in order for the engine to perform its best.

It is important to note that Walbro corporate policy does not certify the use of any of their carburetors for aviation use. It essentially means that Miniplane and those who use their carburetors are "on their own." If Walbro did have carburetors certified for aviation use, they would cost $550 instead of $150. It also means we have no official help or suggestions from Walbro on how to tune their carburetors for paramotor use. If you call Walbro and mention anything to do with aviation, they will hang up on you. The spark plug manufacturer NGK has the same policy and even notes on packaging for their popular paramotor spark plugs that these are NOT for aviation. It is a lawsuit circus in the U.S. with lawyers enriching themselves in every way they can.

The WG was not designed for the Top 80 (or any other paramotor) but for an obsolete Husqvarna chain saw.

Why

the two different ML values? Dave Jewell of Blue Sky PPG suggests

that Miniplane may have failed to update the specifications when they

changed the type of ML diaphragm used in the carburetors many years ago. For a long time, I set ML's to the

same value as on new engines. This was a mistake.

The problems we experienced with the greater value (1.7mm) were poor throttle response and occasional

stalling when suddenly going to full power. In addition, leaning out the high speed mixture with the greater value can overheat the engine and cause permanent damage.

The measured ML value on new

WG's has consistently been 1.7mm (but, of course, this could change at any time). This is also the same measured

value of ML's in the rebuild kits from Walbro. This high value

prevents the ML inlet needle valve from opening fully and results in a

leaner fuel mixture. At

the lower value specified in the Italian Miniplane service manual, the valve

will open fully and deliver the needed fuel to the engine.

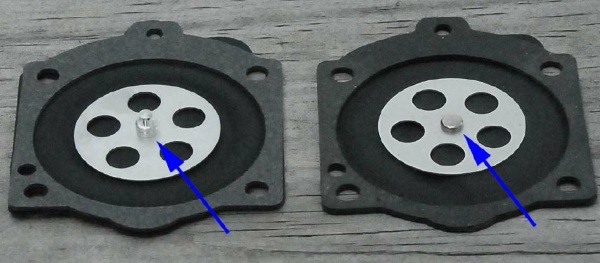

Why do the carburetor rebuild kits and the new carburetors come with the ML value set to 1.7mm? The answer is that rebuild kits that come from Asia and EU have a different ML diaphragm than the kits available in North America (but this is changing). The Asia/EU supplied diaphragm has a tang on it that fits nicely into the slotted end of the ML. It is about 0.38mm higher than the button-type in the kits we usually get in the U.S.

As a result, the carburetors with the tang type diaphragm need to have a ML value of 1.7mm – which is the default value set by the official Walbro metering lever adjustment gauge.

The diaphragm that comes with most of the kits sold in North America do not have a tang but a button. However, some US suppliers of WG8 parts supply kits with the tang type diaphragms. Pilots must examine the diaphragms carefully in order to determine which type they have so they can correctly adjust the metering lever height.

photo courtesy of Wind-Drifter.com

I tested a newly rebuilt engine with both values. With the high

value, sudden operation of the throttle would often stall the engine (it

was briefly starved of fuel). With the low value, I could hit the

throttle quickly to fully open from idle and the engine would immediately accelerate

to full speed without sputtering or stalling. I also wondered whether running at full load

for extended periods might burn up the engine if the higher value of 1.7mm

was used? This is not something I wanted to find out. But we get a bunch of engines in here that have been burned up and I continue to think that the higher ML value contributed

to their overheating problems.

Obviously, engines with the higher ML value will run but may fade when going

to full power or have poorer throttle response. In testing, the maximum ML height for the button-type diaphragm can be 1.3mm. When the value exceeds this, the ML valve is not able to

fully open and the engine may lean out at or near full throttle. For this reason, set the ML to the lower value (0.7mm) but only if your diaphragm does not have the tang. If the ML

value is way less (>0.2mm less than the specified value) the ML valve is forced open at rest and the engine will flood and not idle correctly.

![]()