Redrive belt diagnostics and adjustment

by Had Robinson

NEVER USE BELT DRESSING OF ANY KIND ON A REDRIVE BELT!

A. Introduction

Correct belt tension and pulley alignment will deliver the engine's full power to the propeller and dramatically prolong the life of the belt and the redrive bearings. Go here for detailed information on belt wear issues (from Gates). A loose belt also makes an unclutched engine more difficult to start.

B. Belt issues

New belts

They loosen up quickly. Be sure to re-tension new belts after an hour or two of use.

Chirping

On paramotors running at or near idle speed, the primary cause of chirping is insufficient belt tension. Very loose belts will not chirp but just wear badly. On unclutched engines at or near idle chirping may be pronounced. This is because the propeller acts like a giant flywheel smoothing out the power stroke of the engine. It is harder to hear belt chirping on clutched engines because the redrive is not engaged until the engine is at higher speed, makes more noise, and the power stroke of the engine is not as intense. Even if you do not hear any chirping, it is important to regularly check belt tension.

However, some note that chirping may also be caused by pulley misalignment. This is particularly true of automotive engines.

Chirping is caused when a pulley is misaligned, so that the belt ridges initially contact the sides of the sides of the grooves and then slide downward along the groove’s sides as they seat in the pulley. – from Car Tech

A chirping noise ... can be the result of belt vibration caused by misaligned pulleys – the leading cause of belt noise. As a misaligned multi-ribbed belt span enters the grooves of a pulley, initial contact is made with only one side of the groove. The greater the misalignment angle, the greater the radial sliding length experienced by the belt ribs as the belt seats in the pulley causing frictional vibrations, or chirping. – from Gates

Below, a belt that was ruined because of pulley misalignment and insufficient tension.

Squealing

A high-pitched squealing noise ... normally indicates a lack of tension – the second most common cause of belt noise. Without proper tension a belt will slip, the sidewalls will wear smooth, and the belt will eventually harden through “heat-ageing”, a process referred to as glazing. The more glazed the belt surface is, the more likely it is to make a squealing noise. – from Gates

Glazed, cracking, and damage across the belt ribbing

The belt could just be old and worn out or the correct belt tension was not maintained. Replace the belt.

C. Quick tension check

Give the belt a visual check before use to be sure it is not frayed or about to fail. A belt failure could be a disaster by allowing the engine to quickly over-rev and, possibly, self-destruct.

You can check the approximate tension on a clutched engine by twisting the belt. It should twist about 40 degrees and no more. This is handy if you do not have any tools about, but it is not accurate.

photo courtesy of Fresh Breeze

DO NOT PUT THREADLOCK ON THE SCREW USED TO TIGHTEN THE HOUSING ON THE CONCENTRIC SHAFT!

The instructions and steps below are for the Minari, clutched and unclutched. Other motors are similar.

Refer to the Minari engine diagram for parts identification, as needed.

Special tools required

- 3/8" beam type torque wrench (A click type torque wrench barely works for checking belt tension)

- (2) 6mm hex socket bits (or a bit and a hex key)

- steel ruler – straight edge (used to check pulley alignment)

D. Checking pulley alignment

It is important that the pulleys be perfectly aligned to prevent belt damage. Take a straight edge (a steel ruler or the sliding ruler of a mechanic's square) and place the thin edge on the larger pulley so that it touches as a great an arc as possible on the flats of the pulley. While holding the straight edge firmly, turn the pulley so that the straight edge moves towards the smaller drive pulley. The straight edge should just kiss the flat sides of the smaller pulley. This test ensures that the pulleys are not only parallel but not offset.

The pulley alignment on this engine (photo below) was off by 0.6mm (0.024") which ruined the belt. In addition, the ball bearings of the engine crankshaft and redrive are not designed to support significant axial loads that are experienced when the pulleys are offset. Bottom line: Be sure to correctly align the pulleys.

If the pulleys are out of plane, the entire pulley bracket (part #24) must be replaced. (It was likely bent from a prop strike to the frame or the ground.) On some motors, the engine engine case must be replaced.

If the top pulley is set too far to the front, a shim(s) must be installed between the concentric and the pulley bracket so that the larger pulley will be located more to the rear. Shims are available from Miniplane-USA.

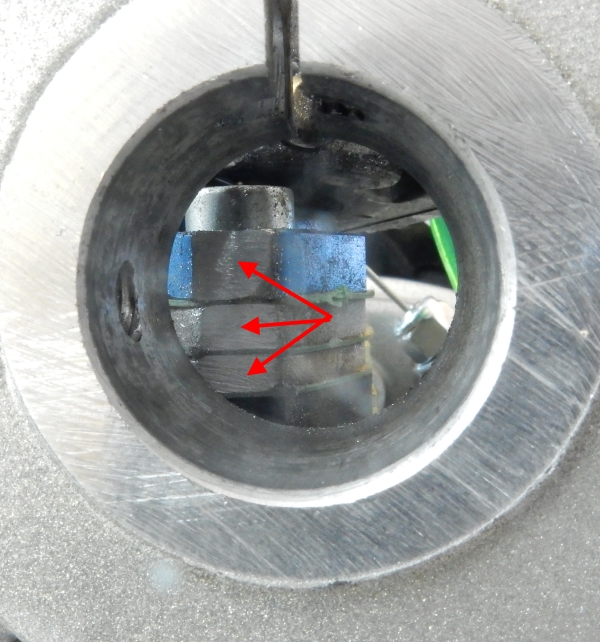

If the top pulley is set too far to the rear, it is most likely that the concentric shaft is hitting against the intake manifold assembly (#56-#60) as illustrated in the redrive of the motor in the photo below. The read arrow points to the end of the shaft where it touches the intake assembly. It is impossible to correctly adjust the pulley alignment, in this case.

Rarely, it might be possible that the rear machined surface of the pulley bracket may need to be carefully filled down so that the concentric shaft can move further forward. What is preventing the concentric shaft from moving forward must be determined and the appropriate measures taken to fix it.

To fix this factory engineering problem, use a thin file to take off some of the surface of the intake assembly as shown below in this photo. It is an easy, non-technical fix that can be done 15 minutes.

E. Checking tension on un-clutched engines

If you have an unclutched engine, you can accurately check the belt tension quickly. Use a beam-type torque wrench with the correct socket to start turning the DRIVE (smaller) pulley while holding the propeller. The pulley should start to slip when the torque wrench reads at least 18 Nm (13 ft. lb). This is the maximum low value. I personally set my belt tension to about 25 Nm (18 ft. lb.). 28 Nm (21 ft. lb.) would be a maximum value. In any case, use the value specified in your motor's manual, if given. Remember that clutched engines will not have belt chirp! Adjust and tighten the concentric per steps #'s1-3 and #8 below, as needed.

F. Checking tension on clutched engines

On clutched engines, the drive pulley will turn freely. The steps and photos below are of the Minari engine, other engines are similar. In particular, the method used to tighten the clamp on the concentric so it will not loosen may be different. Be sure to have the correct torque values needed for tightening the concentric on your particular engine. The pulley should start to slip when the torque wrench reads at least 18 Nm (13 ft. lb). This is the maximum low value. I personally set my belt tension to about 25 Nm (18 ft. lb.) 28 Nm (21 ft. lb.) would be a maximum value. In any case, use the value specified in your motor's manual, if given. If your belt chirps, increase the tension a few Nm's. Adjust and tighten the concentric per steps #'s1-3 and #8 below, as needed.

G. Setting belt tension on both clutched and unclutched engines

1. Locate the re-drive shaft concentric part #82. It slides into part #24, the redrive housing. There is a slit in the housing above the concentric. Put some penetrating oil into the slit so that the concentric can turn easily. The slit is right above the redrive shaft clamping screw (#26). DO NOT USE OIL! If you use ordinary oil, the concentric will slip even when the housing is clamped down tight on the concentric.

Note: The engine below is unclutched but the steps are the same.

2. Loosen the redrive shaft clamping screw (#26) and the concentric shaft holding set screw (#25) below it (some engines may not have this set screw) so that you can easily turn the re-drive shaft concentric (#82) with the hex bit. If you need to remove the concentric shaft, the set screw must be backed out 4-5 turns.

The re-drive shaft concentric has a 6mm cap screw which is used to turn and adjust the concentric (and belt tension). It is accessible from the propeller side of the redrive in the center of the propeller mount. It must turn smoothly and easily so that the belt tension will be set correctly.

3. Make sure the concentric can turn freely With the 6mm hex bit and torque wrench, turn the concentric CCW which will loosen the belt. Once the belt is loose, use the wrench to turn the concentric back and forth in order to be sure it moves freely and easily.

Be certain there are no traces of oil on the concentric. The oil must be completely removed or the concentric will slip when the engine is run under full load.

Before proceeding with the next step, make sure the concentric is fully seated into its housing by firmly squeezing together the pulley and the bracket. If it is not fully seated, the pulleys will not be aligned correctly.

After being sure that the concentric can turn freely, tighten up the clamping screw so that it takes a few Nm of torque to turn it. If you do not do this, the shaft will move slightly out (and out of alignment) as you apply torque to the concentric.

4. Set torque value on the wrench Set the click-type torque wrench to 30 Nm (22 ft. lb.) Note: Use of a beam-type torque wrench will give a much more accurate torque setting.

5. Turn the concentric Begin to turn the concentric in a CW manner (facing the rear of the engine) so that the belt just starts to get snug on the pulleys. Be certain that the belt is correctly seated in both pulleys. Turning the concentric CW will insure that the center bolt in the shaft end of the concentric is not inadvertently loosened.

6. Firmly position hex bit in concentric Be certain that the 6mm hex bit in FIRMLY and COMPLETELY inserted into the cap screw on the end of the concentric shaft. If it is not, the hex bit may ruin the head of the screw so it cannot be removed. With your knee or foot, press down firmly on the rear of engine frame in order to hold it from moving when you torque the concentric screw and secure it at the same time.

7. Torque the concentric screw With one hand on the hex bit that is inserted into the clamping screw and the other hand on the torque wrench, turn the concentric until the torque wrench just reads 30 Nm (22 ft. lb.) or "clicks". Carefully hold the torque wrench in this position while tightening the clamping screw with the other hand. This procedure will set the belt tension to the correct value.

8. Set the concentric Finish by tightening the clamping screw to 20 Nm (15 ft. lb) or the value given for your engine. Also tighten the set screw to 3 Nm (50 in./lb.), if there is one.

9. Check the belt tension!

10. Recheck pulley alignment It is possible for things to move when tightening the belt.

11. New belts Be sure to check the belt tension after the first few hours of use. It takes time for the new belt to completely seat in the pulley grooves and it will loosen after running a bit.

![]()